Blog

What is an Optical Wholesale Lab?

What is an Optical Wholesale Lab? An optical wholesale lab is a specialized facility where prescription eyeglass lenses are produced and processed. These labs play a crucial role in the eyewear industry, bridging the gap between lens manufacturers and eyewear...

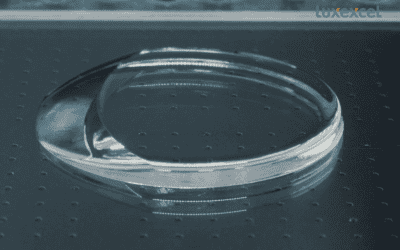

3D Printed Ophthalmic Lenses – Why Not?

When I was young and dinosaurs still roamed the Earth, I began my experience as a trainer with LensCrafters. In their introduction video for new hires, there was a quote that has always stuck with me: “Don’t ask ‘Why.’ Ask instead, ‘Why not?” That kind of thinking was...

Maintenance – Silent Killer or Your Best Friend

Kurt Vonnegut, my favorite author, wrote, “Another flaw in the human character is that everybody wants to build and nobody wants to do maintenance.” Such a true statement - Maintenance is just so important. You go out and buy yourself a nice new car. The years pass...

Self-Refraction Technology Promises Optician Independence (Sort of)

Anything that improves customer experience will benefit brick and mortar opticians and ODs interested in selling eyewear. Separating medical and optical is one the most powerful ways to do just that. New refraction technologies could be the savior of our profession...

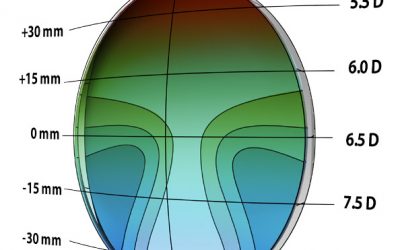

Digging Into Camber

Younger, the company behind the Camber series of lens blanks says, “A progressive lens has many powers, hence it has many ideal base curves, increasing in diopter from top to bottom.” Let’s see if we can dig a little deeper here and figure out just exactly what...

Technology Allows Opticians To Refract Without OD Onsite

You may have felt a disturbance in The Optical Force. However, it was not the Death Star incinerating Alderaan, but Jody Shuler initiating secret plans whereby rebel opticians could deploy a new technology to free themselves from the tyranny and oppression of the...

The AR Coating Process – An Interview with Norm Kester

Nanometers, Colorless AR, and ION Guns, Oh My! Back in 2014, before I worked for Laramy-K, I visited a mid-sized, wholesale optical lab in Virginia that did in-house AR coating. I was privileged to get a behind-the-scenes look at the process. I must admit, while I...

Why Opticians Get No Respect

Eyewear sales make up well over half of all revenue in the eyecare industry. So, why is it then that opticians receive so little in the way of compensation and respect? Could it be they’re playing in the wrong sandbox? Most opticians insist on playing in the medical...

Interview: Laramy-K and The Future of Independent Opticians

John Seegers is a LDO and owner of OpticianWorks.com. Keith Benjamin is Director of Marketing for Laramy-K Optical Lab John: You, well, Laramy-K anyway, is known throughout the industry as a specialty lab capable of producing some unique prescription solutions....

Camber – Revolutionary Lens Technology

David Rips, President of Younger Optics discusses Camber lenses and Laramy-K Optical Lab in the January 2015 edition of LabTalk magazine. 2014 saw the introduction of Camber, a revolutionary new digital lens technology developed by Younger Optics in partnership with...