Integrity Freeform Lenses with

Camber Lens Technology

Camber Lens Technology combines complex curves on both front and back lens surfaces to provide improved vision correction.

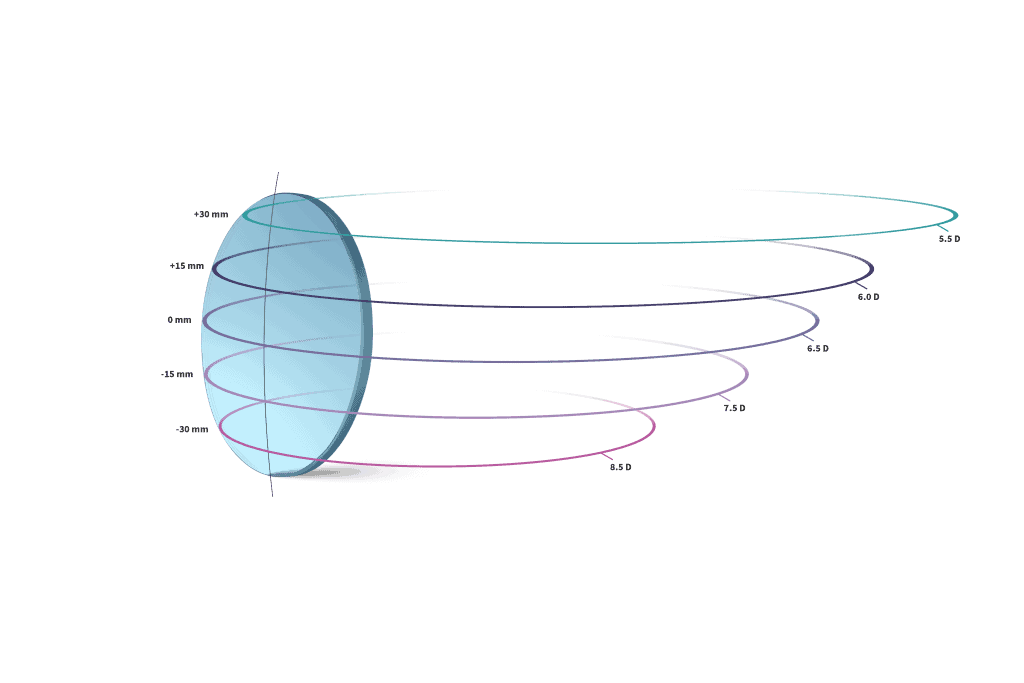

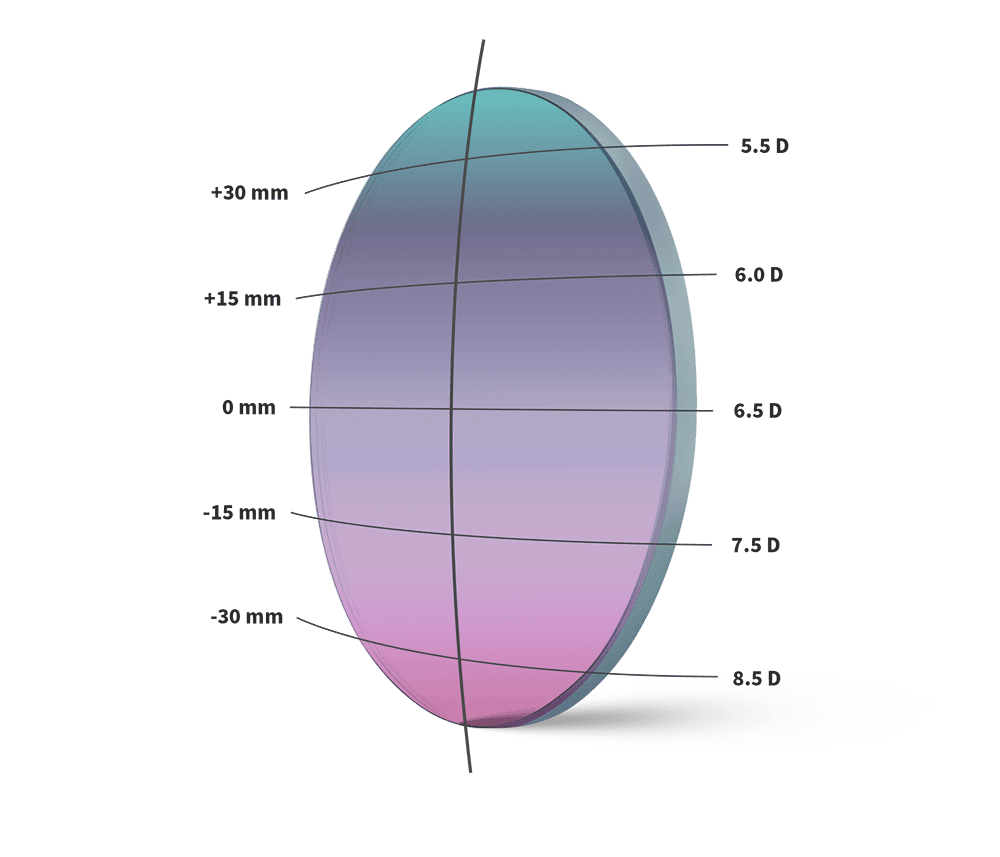

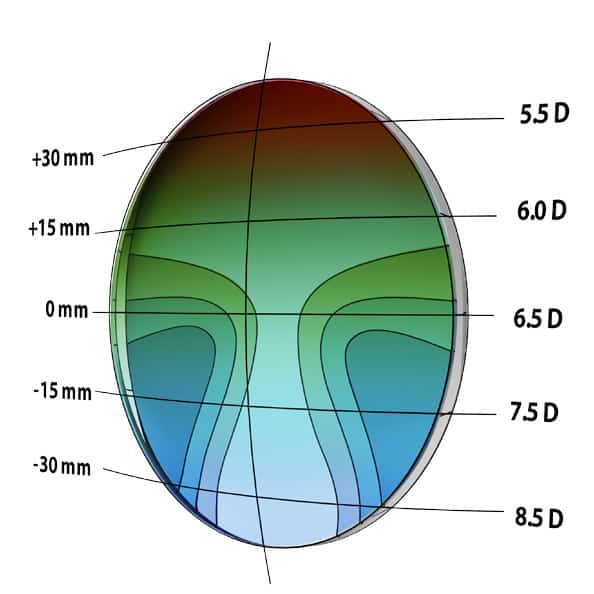

A single progressive lens has many powers; thus many ideal base curves. The distance zone calls for a flatter base curve, while the near calls for a steeper base curve.

The Camber lens blank features a variable base curve, a front surface innovation that provides the optically ideal base curve in all viewing zones.

Components of Camber Lens Technology

The Camber Lens Blank

With variable base curve by Younger Optics, the Camber lens blank improves on the spherical lens blank, by offering a continuously increasing base curve that is better suited for progressive prescriptions.

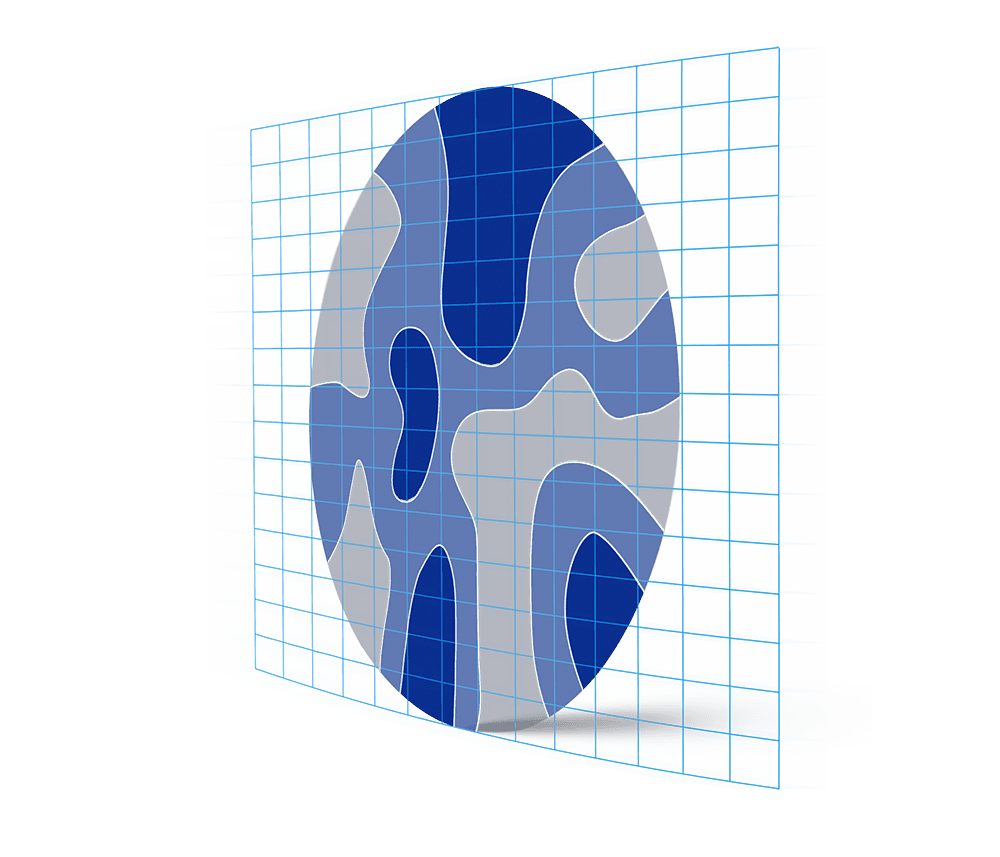

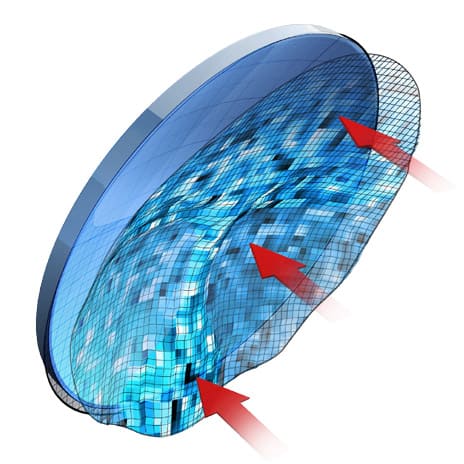

Freeform Design by IOT

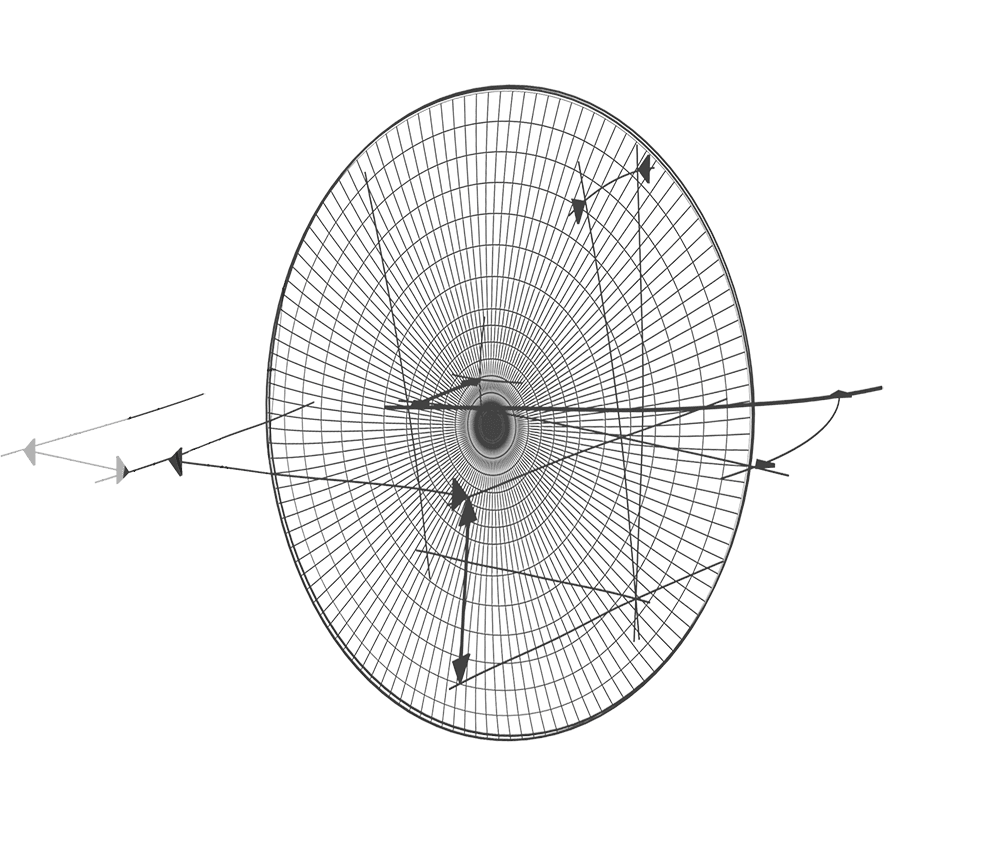

Created with IOT Digital Ray-Path 2 Freeform Technology and Steady Plus Methodology, Camber lens designs are mathematically compensated for peripheral aberrations and include the intelligent use of the wearer’s accommodation to drastically reduce aberrations across the entire field of vision. They also incorporate strict control of mean power to practically eliminate spherical error in lateral areas of the lenses, resulting in improved lateral vision and superior image stability.

Personalized Freeform Lens Parameters

The Rx design computation is further enhanced, when desired, by a complete set of individualization parameters that take into consideration the unique attributes of the frame and the preferences of the wearer. The result is a finished digitally-surfaced lens that is customized for each individual wearer.

Camber Lens Benefits

Improved Vision

Due to the variation of the base curve, the lens is built from the start with a more ideal surface. It provides excellent optical quality at any distance, especially in near vision.

Flatter Lenses

Camber Technology allows the laboratory to select flatter base curves while still giving the wearer the curve they need for maximizing their near vision zone.

In a double-blind study, test wearers compared the same progressive design, one with Camber Technology and the other without it.

%

REPORTED NEAR ZONE EASIER TO FIND WITH CAMBER LENSES

%

REPORTED NEAR VISION QUALITY EQUAL OR BETTER WITH CAMBER LENSES

%

REPORTED EASIER ADAPTATION WITH CAMBER LENSES

GET LAB PRICING AND LET US HELP YOU FIND AN EDGE.

Digging Into Camber Lenses

John Seegers

Younger, the company behind the Camber series of lens blanks says, “A progressive lens has many powers, hence it has many ideal base curves, increasing in diopter from top to bottom.”

Let’s see if we can dig a little deeper here and figure out just exactly what that means...

At this point in my career, my bag of optical sayings is overflowing. One of my all time favorites is this. “In optics you always give up something to get something.” For example, if you want great optics you will wear glass and suffer the weight. If you want the thinnest lens available you will wear 1.74 and suffer the aberration. If you want to wear those super chic, big sunglasses you will suffer with weight and edge thickness.

This saying was brought to mind when I spoke with David Rips, President and CEO of Younger Optics. From our conversation I learned that these lens blanks are about as close as you can currently get to overcoming the optical conundrum of having to “give up something – to get something.”

Before we go any further you need to know that a lens blank is not the same as a lens. In free form, a lens blank is to a lens, what a canvas is to a painting. The blank is the base for the application of design or art. In this case the Camber series lens blanks are (add appropriate here). Then the design software and generators take over and create the back surface design that produces a top-tier, free form progressive like Integrity.

After years of writing for optical industry publications, I am a pretty harsh critic of articles, ads and product brochures. It is not often I give praise, however Younger’s Camber lens brochure is a true stand out! Creative, beautiful, eye-catching and informative, the brochure does a great job of introducing the art and science behind their lens blank series.

You can see for yourself here: The Art and Science of Camber

Although I give well deserved praise on the Camber brochure, I do take issue with its opening statement, “Almost every ECP is familiar with the Tscherning Ellipse below, which indicates the two lens base curves that are optically ideal for each dioptric power.” I must admit I consider myself pretty well schooled in basic optics, but I was not “familiar” with Tscherning’s Ellipse. I am familiar with Vogel’s Rule which states that we are always in search of the perfect base curve – Rx match. Both of the concepts, Tscherning’s and Vogel’s, remind us of the importance of base curve consideration in lens design.

There is a dichotomy here. On one hand, Younger was starting something new and highly technical. On the other hand, it all comes from one of the most basic concepts in optics - base curves. The key to the Camber lens blank series is variable base curve technology. By their returning to the basics they were able to create a lens series with a highly technical design. This lens design features unparalleled optics and advantages over other progressive lens designs.

David points out, “Younger, the world’s largest independently owned supplier of lens blanks, in partnership with Indizen Optical Technologies (IOT), have designed the Camber lens blank series to finally allow the proper synergy between the front and back surfaces of a progressive lens.” Based on our history of working with Younger and IOT, Laramy-K Optical Lab was one of the very first labs to be offered this new lens blank. We have found that in particular hyperopes and those in need of larger intermediates and reading zones benefit greatly from the Camber design. Our customer feedback has been excellent.

David says, “That prior to the introduction of the Camber lens blank series, many labs (not Laramy-K however) relied on one of two choices for progressive lens designs:

1) A blank with a fixed, single curve. These are generally a lens blank designed for a single vision Rx, yet are being used for a progressive.

2) A split design with some features ground or molded on the front surface and some on the back. This design is superior to running a progressive lens from a SV blank, but it is still working with a fixed base curve.”

These two designs are a holdover from when free-form processing was first introduced. It was quickly discovered that by greatly reducing lens stock or SKUs, a lab could save both a considerable amount of money and storage space. This also meant that lens processing was being dictated more by economics than by optics. This, as we well know, does not always produce the best lenses and makes Janet’s head explode. Both of these designs take us back to my initial point. They rely on compromise in one area or another and also violate the basic base curve rules of optics.

It is only through variable base curve applications that free-form technology can be brought to its full potential. In compromised lens design some of the software power is used to compensate for the effects of the imperfect design. This software power is better used creating a perfect lens. It is only when the software can be free to address design based solely on optics that it truly provides the very best lens. Or as David explains, “Rather than focusing every design decision on achieving a fully personalized lens, some of the design power must go toward compensation correction.”

Another one of my favorite optical sayings is this, “The shorter the radius, the steeper the curve - the steeper the curve, the higher the power - the higher the power, the thicker the lens (in a given material). It was chant I had my students memorize and recite. Grab a Camber brochure and take a look at Figure 6.1 The Elephant’s Trunk Curve. It took me a moment to let it sink in. But once it did, there it was! My favorite optical saying, presented in a very cool graphic form.

On page 11 of the brochure, a highlight is, “easier frame selection because higher base curve prescriptions have fewer frame limitations.” I asked David to explain that.

He replied, “Let’s look at an Rx with a high add. In a traditional lens blank selection you would be forced into choosing a +8.00 base curve to achieve the necessary power at the add. This would force you to use a +8.00 curve across the entire range of the Rx. When you choose a Camber design, you will have the correct lower base curve filling your distance Rx while only the area in front of your add will have the full +8.00. You will obviously end up with a lens with a flatter overall base curve, superior optics and in many areas, a thinner bevel.”

The Camber lens series is currently available in hard resin, polycarbonate, Trilogy – Trivex, 1.60 and 1.67. Clear, NuPolar polarized and Transitions Signature VII are available. Laramy-K processes the series on its Schneider Sprint Line 2 generators, of course running IOT software.

For you and your customers Younger says, “In a Younger/IOT double blind test 100% of wearers reported an easier to find near zone. 83% of wearers found easier adaptation and 94% reported near vision equal to or better than conventional lens designs.”

If you take a few moments to read through the entire Camber brochure, and get to page 10, you will notice a rather shocking bit of information. Look at the chart “Hierarchy of Importance.” Isn’t it refreshing to see the ECP on top for a change? Isn’t it nice that after years of tormenting free-form language play and technological jargon, you see that you are still the most important piece in the puzzle!

Sometimes to move ahead, we first need to take a step back and reexamine the basics before taking another step forward. A big thank you goes out to Younger and to David for bringing our attention back to the importance of base curves and to the importance of ECPs too! It was a pleasure to speak with him and it is always energizing to hear true passion about the importance of what we do.

Call us with any questions you have about trying Camber technology for your customers. 1-800-525-1274

Camber and Laramy-K in the Media

David Rips, President of Younger Optics discusses Camber lenses and Laramy-K Optical Lab in the January 2015 edition of LabTalk magazine.

2014 saw the introduction of Camber, a revolutionary new digital lens technology developed by Younger Optics in partnership with IOT. Camber lenses are now being offered by a growing number of independent laboratories, most of whom market Camber lenses under a house brand of digital lens designs.

Independent laboratory Laramy-K Optical offers its brand, Integrity Freeform lenses, with Camber technology. Owner Janet Benjamin says, “We offer Camber lenses because they are simply the best technology in the market today. For Laramy-K, benefiting the wearer is the biggest benefit to us as a company.”

How does a Camber lens differ from a standard back-side digital progressive lens? It starts with an innovative new lens blank design, one that features a continuously increasing base curve from the top to the bottom of the lens. This helps to provide the appropriate base curve in each zone of the lens. Its sophisticated back surface digital design is enhanced with IOT’s Digital Ray-Path technology. Once processed, both surfaces work in tandem to create the Camber finished lens design, which offers expanded reading zones, improved peripheral vision, and a more cosmetically appealing (flatter) finished lens shape. A wearer [and master optician] in Israel writes, “I am amazed with this design. It feels just like single vision. There is absolutely no distortion at the edges. I think this is the best progressive I’ve had in 30 years.”

Camber lenses are available in five materials, in 8 base curves. NuPolar and Transitions Signature styles are also available.

Integrity Freeform Lens Technologies from IOT

Essential (Basic)

Steady Methodology

Non-Compensated Design

Essential is the entry-level technology for digital lenses. The progressive surface is calculated using IOT's Steady Methodology providing improved performance over conventional progressive lenses, with the accuracy and flexibility of the digital freeform process.

Endless (Advanced)

Steady and Digital Ray Path 2

Compensated Design

Endless is the most advanced technology used to make digital lenses. Endless combines IOT's Digital Ray-Path® 2 and Steady Methodology to take into account the real measured or default wearer position of the lens and the natural movements of the human eye.

Camber

Camber, Steady+, and DRP2

Compensated + Camber Blanks

Camber Technology combines Endless technology with a unique, lens blank with a steepening base curve in the direction of the add power . When combined with IOT's Digital Ray-Path® 2 and IOT's Steady+ Methodology, both surfaces work together to expand power ranges, offer better cosmetics, and widen intermediate and near vision zones.

* When comparing to other brand's "good better, best" options, it is important to note that the "Advanced" technology is equivalent to the "best" on the market, while Camber takes it to another level, incorporating the Advanced technology PLUS the special Camber lens blank, making it unlike any other lens available. What's more, you easily choose the ideal design for your customer or patient based on Rx or lifestyle and THEN select from "good, better, best" ensuring the most ideal and customized outcome for their visual needs.

Steady Methodology

Learn More

Digital

Ray-Path 2

Learn More

Camber

Technology

Learn More